This vintage video shows a small scale biomass fuel operation in Finland. The biomass fuel producer is a farmer in South-Western Finland who has been heating his farm with woodchips since the 1970s. He produces wood-energy chips for the heating of his own farm and a few customers like a local factory and some houses.

The video shows the harvesting operation with an accumulating harvester head, transport with the forestry trailer, piling for seasoning in the forest, chipping, active drying of the woodchips, transport to the heating plant and the return of the ashes as fertilizer into the forest.

This whole operation is run by one single person. Most important tool is the forestry tractor and all the attachments to make the operations.

Harvesting the biomass

The harvest for biomass fuel in Finland is done during the thinning operations of the forests. These operations are part of the new forest practices that are implemented in Finland since the 1960s and are the main reason why Finnish forests store now more carbon than ever. Good forest maintenance practices leave more space for trees to grow, meaning stronger trees that are less affected by illnesses and forest fires. The other stream for biomass fuel is all the leftovers from commercial logging operations and sawmills: treetops, branches, hog, surface boards…

The harvesting of biomass fuel during thinning starts with an accumulating harvesting head, also called accumulating energy wood head like the E25 from Naarva on the picture above. The accumulating harvesting head is mounted on a crane on a tractor or a small excavator. It is able to cut multiple small trees before felling the whole bunch on the floor. This makes the harvesting operation efficient and cost-effective.

The harvested wood is piled near a forest road with a forestry trailer. Then it is left to dry and may be covered with a waxed cardboard to reduce the exposure to rain and snow.

Making biomass fuel

After seasoning, the wood has naturally dried to be around 35% of moisture content, which is dry enough to avoid fermentation in the woodchip pile. All of Säätötuli’s heating equipment are guaranteed to work with woodchips up to 35% moisture content.

Once seasoned, the wood can then be transformed into fuel with a biomass chipper like the FarmiForest CH260 on the picture above.

Moisture content of the biomass fuel

It is of utmost importance to never chip and store freshly cut wood. Woodchips with over 35% moisture content will begin to heat under the natural fermentation process induced by bacteria and mould. This fermenting process will destroy a part of the energy of your woodchips, making your biomass fuel less efficient. The increase of temperature in the woodchip pile will increase the drying speed, but it will do so with two major downsides. First of all, fermenting can become strong enough to spontaneously combust part of the woodchip pile, increasing the risk of fire. The second danger is that the bacteria and mould responsible of the fermentation will produce spores in the woodchip pile. Those spores will become airborne when the woodchip pile is moved with a loader and can easily go in the lungs of the loader operator. There are only a few studies of the effect of cumulating bacterial spores in the lungs, but it is a risk not worth taking when there are easy solutions to avoid it.

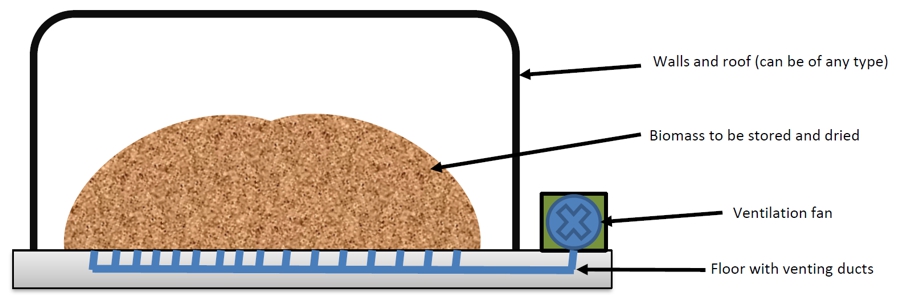

If letting the wood season is not an option, the economic woodchip dryer above is a possible solution. This type of dryer is also featured in the video. It is simply a barn (or even a tent) with a floor that has been modified in order to be able to push an airflow through. The airflow is provided by a fan that is simply connected to a hygrometer to stop the airflow when it’s raining. The air can be heated to increase drying speed, but even fresh air will be enough to avoid the fermentation of the woodchips. This kind of dryer can be filled with a layer of about 3 feet (1 meter). Once the first layer is dry, a second one can be chipped on top of it. In summertime, this takes about 2 weeks per layer.

Once the biomass fuel is burnt in a boiler, the remaining ashes will be sent back to the forest and used as fertilizer. The ashes contain mostly the minerals that were embedded in the wood, therefore it is logical to return them to the forest. The ashes are tested for heavy metals before being spread back to the forest.