A robust biomass silo solution: Säätötuli Hydrobar

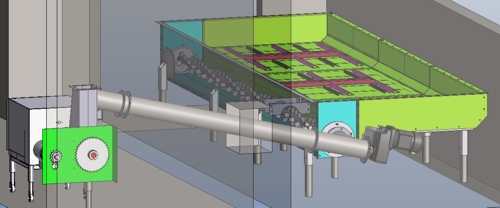

The Säätötuli Hydrobar is designed to be the bottom of a biomass silo. Hydrobar is equipped with hydraulically operated scrapers (green in the picture above) which move the fuel to a feeding auger. This feature allows to process a large number of different biomass fuels and reduces their tendancy to form vaults inside the silo. The Hydrobar is available for sizes between 1 x 1.5 meter, up to 3 x 4.5 meter. Säätötuli Hydrobar can be loaded with up to 6 meters of fuel in height.

This video is also available on YouTube: Hydrobar biomass silo discharger in video

Hydrobar is available for biomass burners from 136,000 BTU/hr (40kW) up to 1,706,000 BTU/hr (500kW).

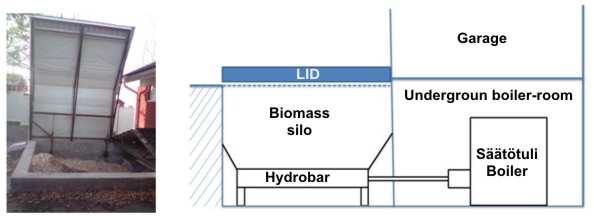

Hydrobar allows easy installation of a biomass silo in versatile conditions. It can be used to make an underground biomass silo as in the picture above, or a cheaper above-ground silo simply by adding metal walls on the unit. Hydrobar is also the most common silo-element in Säätötuli’s containerised biomass heating systems.

Hydrobar allows easy installation of a biomass silo in versatile conditions. It can be used to make an underground biomass silo as in the picture above, or a cheaper above-ground silo simply by adding metal walls on the unit. Hydrobar is also the most common silo-element in Säätötuli’s containerised biomass heating systems.

Säätötuli Hydrobar is usually connected to a Säätötuli water boiler or a Säätötuli hot air generator and equipped with a Säätötuli C2XX, C4XX or C5XX-series touch-screen automation.

Säätötuli Hydrobar is usually connected to a Säätötuli water boiler or a Säätötuli hot air generator and equipped with a Säätötuli C2XX, C4XX or C5XX-series touch-screen automation.

Säätötuli Hydrobar can be connected to third-party boilers or used as retrofit on existing boilers. If you have a retrofit project or a third-party boiler, your can ask your local Säätötuli reseller or representative if your current equipment will be able to accommodate a Säätötuli burner.

Great with difficult fuels and low maintenance needs

The scraper concept of the Säätötuli Hydrobar is quite alike the hydraulic scrapers on an industrial-size biomass plant. Therefore Hydrobar is able to process quite difficult fuels, such as wood chips with bigger quantities of fine particles, peat, different agricultural residues…

All the mechanical parts are located under the Hydrobar. Unlike spring arm silo dischargers, Hydrobar never requires to empty the silo in case of a mechanical problem. Moreover, the moving parts are actuated by strong hydraulic cylinders, meaning that maintenance is easy and mechanical breakdowns are almost non existent.