Säätötuli’s Biocont MultiJumbo is a containerised plant designed for district heating and other applications with large heat-energy needs. Biocont MultiJumbo is highly customizable and can be used with containerised or fixed biomass silos. They can also include backup boilers running with fossil fuels and power generators to be able to operate even if hydro is down. Several Biocont MultiJumbo plants are in use in Northern Europe as primary or secondary biomass heat plants for municipal district heat networks.

Säätötuli’s Biocont MultiJumbo is a containerised plant designed for district heating and other applications with large heat-energy needs. Biocont MultiJumbo is highly customizable and can be used with containerised or fixed biomass silos. They can also include backup boilers running with fossil fuels and power generators to be able to operate even if hydro is down. Several Biocont MultiJumbo plants are in use in Northern Europe as primary or secondary biomass heat plants for municipal district heat networks.

Biocont MultiJumbo technical specifications

2,559,000 BTU/hr (750 kW)

2,900,000 BTU/hr (850 kW)

3,412,000 BTU/hr (1000 kW)

5,118,000 BTU/hr (1500 kW)

![]()

The automation can be based on Unitronics PLCs like the standard Säätötuli automations, or Siemens PLC controls when a high level of automation and customization is required.

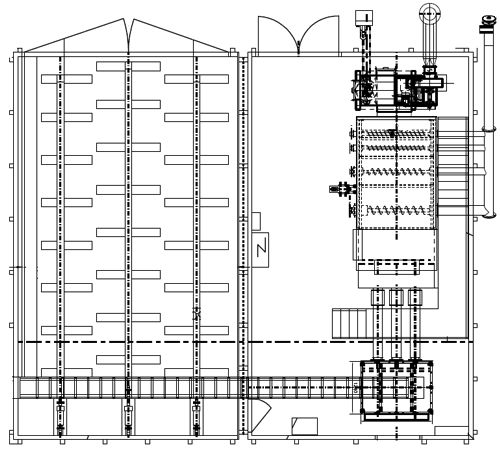

Automatic ash removal

This system will evacuate the ashes from the firebox to a box outside of the containerised biomass plant. The number of augers will depend on the boiler output. In some cases, the multi-cyclone may also be equipped with automatic ash removal.

Automatic flue gas extractor and Multi-cyclone flue gas cleaner

Having a chimney with a good draft is an essential feature on a biomass boiler for good combustion and security. All our containerised biomass heating plants are always equipped with an automated flue gas extractor that will set the draft in real-time according to the pressure inside the firebox of the boiler. The multi-cyclone helps to clean the flue gas from particulate matter. It is a simple and easy-to-maintain solution that will ensure that your biomass boiler plant will meet the environmental regulations.

Several Security PLUS packs

All the conveyors inside the Biocont MultiJumbo are secured against backfires with automatic sprinklers.

Lock-feeder

For increased backfire security, the conveyor coming from the silo is dropping the fuel in a buffer-silo with an airtight automated hydraulic lock. This ensures that the fire will never be able to travel backwards in the silo.

Automatic exchanger-tube cleaning

The tubes in the heat-exchanger of the boiler will accumulate dust during the use of your biomass boiler. Depending on the fuel you use, the cleaning requirement for these tubes can be quite high. The automatic tube cleaning system will help you with this task by adding moving spring-like elements in the tubes to maintain them as clean as possible. Depending on the model of the boiler, this system may also work with compressed air that is sent to the tubes.

Energy meter

As the Biocont MultiJumbo is designed with district heating in mind, several energy-meters are installed in order to always know the output of the heating plant and how much heat every loop of the network is using.

Piston-feed biomass burner

Traditionnally the biomass burners are fed with one or several augers pushing the biomass fuel on the burning grate. The new high-tech alternative is to have a hydraulic piston feeder for the burner. The piston feeder allows for better performance with difficult fuels.

Wet boiler ash removal

The ashes produced during the combustion of the biomass will mostly drop down from the combustion grid in the ash-box and some of them will fly out with the hot combustion gases. The wet boiler ash removal is the latest solution to improve the environmental performance. The whole bottom of the boiler has a water layer with a rake conveyor underneath. The ashes from the combustion grid will drop down on the wet conveyor, but also flue gases that will go through the exchanger will loose a part of the flying ash when the gases meet the water at the bottom of the exchanger. This eliminates also all the risks related to hot ashes.

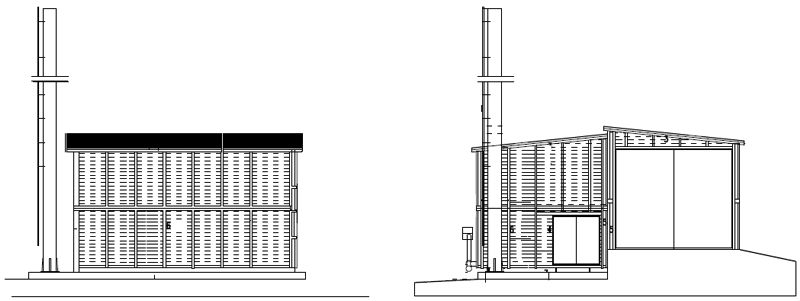

External dimensions of Biocont MultiJumbo

The external dimensions of the Biocont MultiJumbo will depend a lot about the output of the biomass boiler and the volume of the biomass silo. For district heating applications, the biomass silo is commonly quite big as it has to be able to hold about two weeks worth of woodchip fuel at full power, which in many cases means a handful of truckloads. Commonly the footprint of the Biocont MultiJumbo will be around 40 x 33 feet (12 x 10 meters).

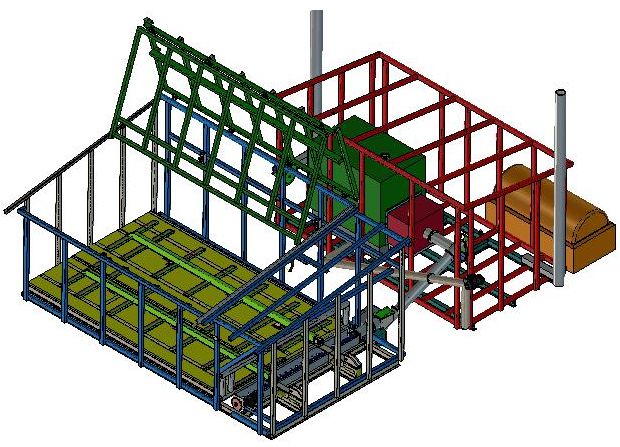

Like all Säätötuli’s containerised biomass heating plants, the Biocont MultiJumbi is also made with an external structure made with tubular steel and fire-proof sandwich-panel roof and cladding. Due to the great size of these district heating plants, the structure is usually divided in smaller parts that will be easier to transport. The different parts are put back together at the installation site. You can see how this is done on our case study on the installation of a Biocont MultiJumbo.

Internal lay-out

The basic lay-out of the Biocont MultiJumbo includes a boiler-room with a large hot water biomass boiler, the automation and electric panels, a buffer-silo for the fuel coming from the biomass silo, and all the piping and other equipment needed. In district heating applications, it is also common to have a high level of redundancy on the piping and pumps, and also a backup boiler and genset to ensure 24/7 operation.

The Biocont MultiJumbo is connected to a hydraulic scraper biomass silo station. That station can be totally containerised, but the floor is usually made at site with concrete and embedded hydraulic scrapers. The floor-scrapers are designed so that delivery trucks can back directly on the scrapers to dump the fuel.

Customizable solutions for district heating

The Biocont MultiJumbo can be highly customized to meet the customer’s needs. For example on the pictures above, the red heating plant has a huge biomass silo at the rear and two Biocont MultiJumbo heating plants working in tandem. The second MultiJumbo was added some years after the first one as the greenhouse it was heating did undergo a large extension. The biomass silo was large enough for both heating plants, so the biomass conveyor between the silo and the boiler was modified in order to send fuel to both boilers.

The white district heating plant was built on a slope and the roof of the silo is hydraulically operated. That way delivery trucks can dump fuel in the biomass silo at a higher altitude, meaning that the total footprint of the heating plant could be downsized.

The Biocont MultiJumbo can be equipped to meet all the needs for a small municipal district heating network. On the picture above, the main boiler room is the building on the left with the door and the window. The small adjacent part houses the ash container and the genset providing electrical current when hydro power is cut. A high level of redundancy is built-in and all alerts are automatically sent to several persons to ensure a smooth 24/7 operation. Legally in Finland a municipal district heating network is not allowed to be out of service more than one hour during winter time.