With solid fuels, the fuel storage silo and its ability to transfer the fuel from the silo to the burner is of primarly importance. Säätötuli manufactures many different silo solutions in order to provide a good solution for every single project.

Säätötuli can provide the following equipments:

– Säätötuli STRONG-series from 40kW (136,000 BTU/hr) up to 80kW (273,000 BTU/hr)

– Säätötuli Hydrobar: a robust multi-fuel solution from 40 kW (136,000 BTU/hr) up to 500 kW (1,710,000 BTU/hr)

– Industrial hydraulic-scraper silo-stations from 120kW (400,000 BTU/hr) and up

Säätötuli biomass conveying augers for lowly screened fuel

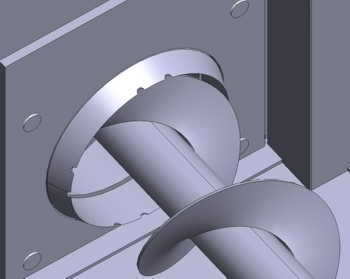

Säätötuli started as an agriculture-industry oriented biomass boiler builder. Since the beginning, Säätötuli’s boilers have been challenged by “home-made” lowly screened biomass fuel that is difficult for any feeding mechanism to convey. Therefore, all the feeding augers in Säätötuli’s installations are strong and designed to be able to handle the most difficult of fuels. The silo auger, like on the picture above, is made with Säätötuli’s special design allowing stick-like material to be crushed while the screw turns, thus correcting most parts of low screening in fuels.

Säätötuli started as an agriculture-industry oriented biomass boiler builder. Since the beginning, Säätötuli’s boilers have been challenged by “home-made” lowly screened biomass fuel that is difficult for any feeding mechanism to convey. Therefore, all the feeding augers in Säätötuli’s installations are strong and designed to be able to handle the most difficult of fuels. The silo auger, like on the picture above, is made with Säätötuli’s special design allowing stick-like material to be crushed while the screw turns, thus correcting most parts of low screening in fuels.

A specially designed counter-blade is installed at the entrance of the conveying tube in order to cut oversized materials before they enter the feeding auger. Sturdy auger conception and powerful motors ensure that even big chunks of wood are cut and do not block the feeding system.

Säätötuli can manufacture augers of different sizes and combine many augers, including upward-going augers and drops in order to fit exactly between the fuel silo and the biomass boiler at any site.

On bigger boiler plants, Säätötuli can also use conveyors instead of augers between the fuel silo and the boiler.

What do you need for a biomass heating system?

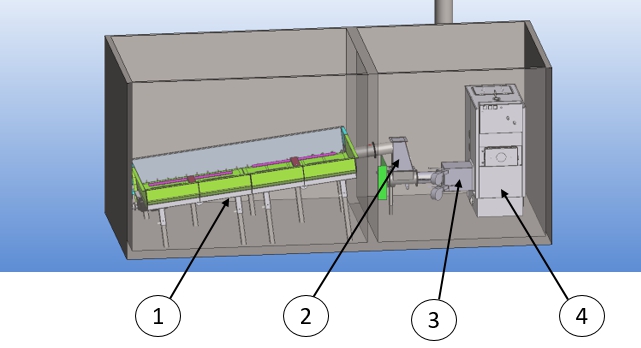

Principal elements of a Säätötuli hot water biomass heating system:

1 – Fuel silo (like the Säätötuli Hydrobar on this picture)

2 – Fuel conveying system including safety features

3 – Säätötuli burner

4 – Säätötuli boiler

In addition, you have to add:

– Chimney (possibly with smoke extractor)

– Automation

– Optional ash conveying system

– Optional flue gas cleaning system