The Säätötuli biomass hot air generator has been jointly developed with a Finnish expert in grain drying technologies. First unit was fired in 1994 and is still working in Finland. During the years, many improvements have been made. Säätötuli’s hot air generator is recognized in Scandinavia for having the lowest maintenance costs and longest life-expectancy.

Designed at first for agricultural use, the Säätötuli hot air generator has since been used in many different applications such as heating of industrial and agricultural buildings, heating for underground mines, wood-chip drying and waste treatment.

The biomass hot air generator is equipped with lamellar convection made with stainless and acid-proof steel. This ensures that the hot air is never in contact with the combustion smoke which is sent to the chimney.

You will find more details about the hot air generator in the brochure you can download below. For more precise technical specifications, please contact our sales.

The Säätötuli hot air generator is able to burn a wide range of solid fuels, including energy-chips, wood industry leftovers, pellets, peat, agricultural residues…

The Säätötuli hot air generator is able to burn a wide range of solid fuels, including energy-chips, wood industry leftovers, pellets, peat, agricultural residues…

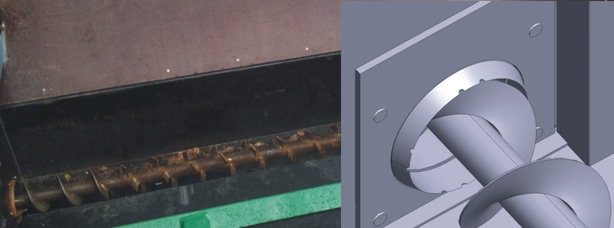

The Säätötuli Hydrobar feeding auger is based on the same technology as industrial solid-fuel plant silos. It is able to accept fuels with low quality screening. The conveying auger is designed to break sticks and a round blade will cut any particle too big to fit in the feeding tube.

The Säätötuli Hydrobar feeding auger is based on the same technology as industrial solid-fuel plant silos. It is able to accept fuels with low quality screening. The conveying auger is designed to break sticks and a round blade will cut any particle too big to fit in the feeding tube.

If the hot air generation plant needs a huge silo, the Säätötuli hot air generator can be connected to a hydraulic scraper station of several hundreds of cubic meters.

The hot air generator is driven by an intuitive touch-screen program. User language can be chosen at startup. Säätötuli uses only standard electrical components for its automations. In case of any problem, a local electrician will probably have the necessary components in stock and you will never have to wait for expensive parts from the factory.

The hot air generator is driven by an intuitive touch-screen program. User language can be chosen at startup. Säätötuli uses only standard electrical components for its automations. In case of any problem, a local electrician will probably have the necessary components in stock and you will never have to wait for expensive parts from the factory.

The feeding system is always equipped with a Säätötuli security pack with automatic sprinklers or aerosol extinguishers. This eliminates the risk of backfire going into the silo. Usually the feeding system also includes a drop or a fuel-lock for increased security.

The feeding system is always equipped with a Säätötuli security pack with automatic sprinklers or aerosol extinguishers. This eliminates the risk of backfire going into the silo. Usually the feeding system also includes a drop or a fuel-lock for increased security.

Säätötuli’s hot air generator has an output of 1.700.000BTUs/hr (500kW). If the power-need is bigger than the output of the Säätötuli hot air generator, it is easy to combine several generators in order to increase power output.

Säätötuli’s hot air generator has an output of 1.700.000BTUs/hr (500kW). If the power-need is bigger than the output of the Säätötuli hot air generator, it is easy to combine several generators in order to increase power output.

Download brochure (PDF)

Download brochure (PDF)