The Biocont Eco is an economical biomass heat-energy box equipped with a roll-off hook.

The Biocont Eco is an economical biomass heat-energy box equipped with a roll-off hook.

Technical specifications of the Biocont Eco biomass heat-energy box

546,000 BTU/hr (160 kW)

682,000 BTU/hr (200 kW)

Säätötuli C110

Basic automation with 2-line digital screen.

The language of the software is set at the factory, the customer can choose the language when ordering the heat-energy box.

Säätötuli C210

Basic automation with intuitive touch-screen software.

The user can chose the language for the software (English, French and other choices available).

Säätötuli C210 modulating

Same features as the C210, but adds modulation of the output of the burner (idle/run on the basic model).

All C210 automations can be upgraded with a GSM modem to send alerts by text messages to cellular phones.

Please note that regional requirements may affect the choice of automation, like in Ontario where idle-mode is forbidden for biomass boilers and a data recorder has to be added.

Automatic flue gas extractor

Having a chimney with a good draft is an essential feature on a biomass boiler for good combustion and security. All our containerised biomass heating plants are always equipped with an automated flue gas extractor that will set the draft in real-time according to the pressure inside the firebox of the boiler.

Security PLUS pack or Aeromag aerosol extinguisher

The Security PLUS pack consists of two sprinklers placed in the feeding augers between the silo and the boiler. The sprinklers are connected to automated mechanical valves that will open the waterflow if the sensor on the auger detects a temperature raise indicating that fire is trying to get from the burner to the silo.

The Security PLUS pack is replaced by Aeromag aerosol extinguishers if the customer is using pellets. Water would expand the size of the wood pellets more than double resulting in jammed augers.

Drop feeder

For increased backfire security, the auger coming from the silo and the auger going in the burner are separated by a drop feeder. The drop feeder will simply drop the biomass fuel coming from the silo to the burner auger. Automation controls a sensor placed on the silo auger. If the temperature of the silo auger raises to an abnormal level, the drop feeder will stop the silo auger and run the burner auger in order to create an empty space between the firebox and the fuel from the silo.

Automatic ash removal with two augers

This system will evacuate the ashes from the firebox to a box outside of the containerised biomass plant.

This option can’t be mounted with the C110 automation box.

Multi-cyclone

The multi-cyclone helps to clean the flue gas from particulate matter. It is a simple and easy-to-maintain solution that will ensure that your biomass boiler plant will meet the environmental regulations. Säätötuli will be happy to assist you to select the best flue gas cleaning solution depending on your local regulations. The multi-cyclone is mounted in a box outside the Biocont Eco.

Automatic exchanger-tube cleaning

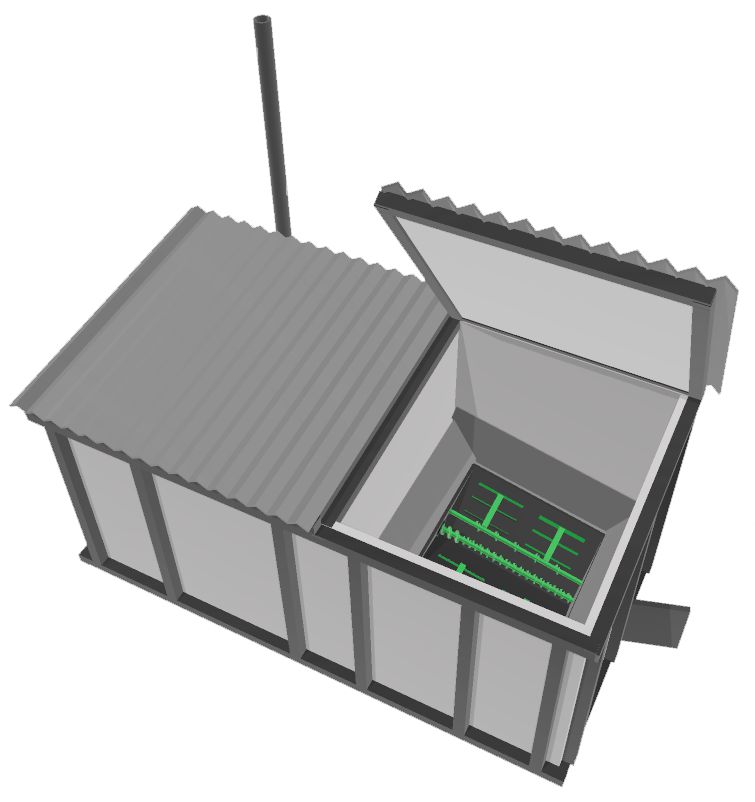

The tubes in the heat-exchanger of the boiler will accumulate dust during the use of your biomass boiler. Depending on the fuel you use, the cleaning requirement for these tubes can be quite high. The automatic tube cleaning system will help you with this task by adding moving spring-like elements in the tubes to maintain them as clean as possible. The roof of the Biocont Eco biomass heat-energy box has a hatch to service the boiler and allow for the automatic exchanger-tube cleaning to be removed for maintenance.

Energy meter

If you want to know your exact heat consumption, or if you want to sell the BTUs your Biocont Eco produces, the biomass heat-energy box can be equipped with an energy meter.

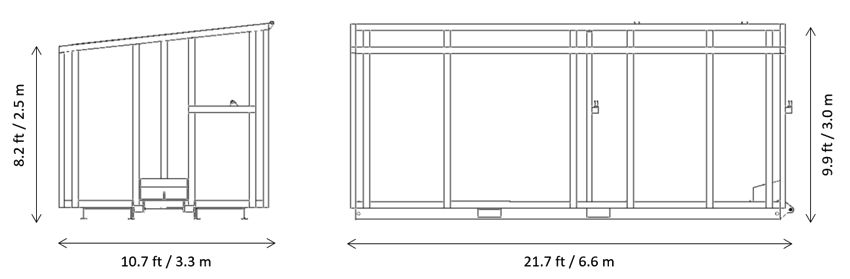

External dimensions of the Biocont Eco biomass heat-energy box

Like all Säätötuli’s prefabricated biomass plants, the Biocont Eco is made with an external structure made of tubular steel and fire-resistant sandwich-panel cladding and roof. Colors can be chosen and it is possible to add an additional paneling outside for decorative purposes.

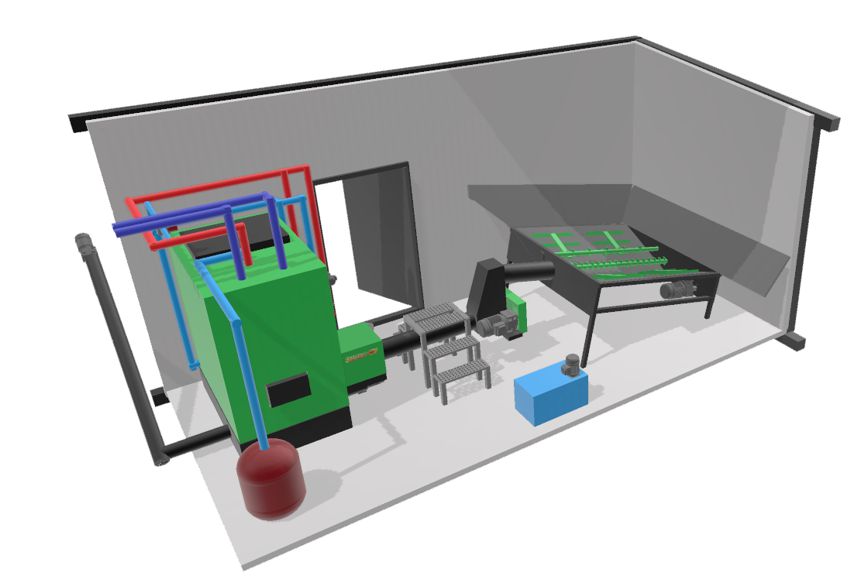

Internal lay-out

The Biocont Eco is a compact biomass heat-energy box divided in two major areas described below.

The boiler-room has also the main electrical box of the boiler plant and the control box.

It has also all the piping needed to operate the boiler (including expansion tank) and the inlet and outlet for the heat network.

The boiler room houses also the hydraulic unit needed to operate the roof of the silo and the moving grate of the burner.

The bottom of the silo features a Säätötuli Kaks2 biomass silo discharger. The Kaks2 silo discharger is installed at an angle so that the discharge auger will move the fuel upwards to the boiler-room part.

The silo is also equipped with a maintenance hatch that allows access under the Kaks2 unit for maintenance operations.

Roll-off hook

The Biocont Eco is particularly easy to relocate. Just as the Biocont Roll-off, it features a roll-off hook at one end of the self-contained boiler plant. This allows roll-off trucks to move the whole plant with no help from any cranes or additional handling equipment.

All the piping around the boiler is factory-mounted. This includes the expansion bowl, the boiler’s looping circuit (extends the lifespan of the boiler by avoiding cold return water) and the pressure-release valves. There can be one or two heat-network loops directly connected to the biomass heat-energy box. The pumps for the heat-networks are included. The inlet/outlet of the heat network can be installed inside or outside the biomass heat-energy box.

All the piping around the boiler is factory-mounted. This includes the expansion bowl, the boiler’s looping circuit (extends the lifespan of the boiler by avoiding cold return water) and the pressure-release valves. There can be one or two heat-network loops directly connected to the biomass heat-energy box. The pumps for the heat-networks are included. The inlet/outlet of the heat network can be installed inside or outside the biomass heat-energy box.

The silo part of the Biocont Eco biomass heat-energy box has a hydraulically operated roof and a service hatch to access underneath the Kaks2 silo discharger for maintenance operations.

The silo part of the Biocont Eco biomass heat-energy box has a hydraulically operated roof and a service hatch to access underneath the Kaks2 silo discharger for maintenance operations.